Alternator test rig

Alternator test rig Specification

- Temperature

- 5C to 50C

- Hardness

- Industrial grade steel frame

- Display Type

- Digital LCD

- Response Time

- 2 seconds

- Accuracy

- 1%

- Max Height

- 1200 mm

- Frequency

- 50 Hz

- Mounting Type

- Floor mounted

- Port Size

- 1 inch

- Interface Type

- RS232 / USB

- Number of Specimens

- 1 unit per test

- Resolution

- 0.1A

- Operating Voltage

- 230V AC

- Power Supply

- 230V AC, 50Hz

- Usage

- Automotive component evaluation

- Capacity

- Up to 15 kW

- Machine Weight

- 400 kg

- Test Speed

- Up to 3000 RPM

- Test Width

- Standard: 450 mm

- Test Stroke

- Adjustable, Up to 200 mm

- Control Mode

- Digital / Manual

Alternator test rig Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Packaging Details

- CARTONS BOXES / WOODEN BOXES WITH THURMAKOL

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO : 9001 , 2008

About Alternator test rig

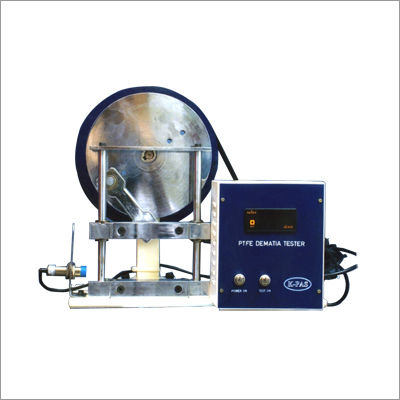

Alternator Test Rig

Designed and manufactured to perfection, our company is considered as one of the renowned and preeminent manufacturers and suppliers of Alternator Test Rig. In order to meet the ever rising needs of the clients, we are manufacturing an ample range of test rig for them, with the aid of our expert team of workforce. Our Alternator Test Rig range is highly acknowledged in the market for its distinctive features such as compact design, less power consumption and impeccable performance.

Precision Control and Versatility

This test rig utilizes a 5 HP AC drive motor and supports speeds up to 3000 RPM. Operators can choose digital or manual controls for detailed adjustments. With adjustable test stroke up to 200 mm and a digital LCD display, the rig accommodates a range of alternator test protocols, ensuring flexibility and advanced data capture for laboratory or workshop use.

Safety and Reliability Guaranteed

Designed with operator safety in mind, the rig offers built-in emergency stop mechanisms, circuit breakers, and low vibration design for secure operation (1.5 mm/s). The protection class IP54 shields critical electrical components from dust and splashes, while its industrial steel frame underscores long-term reliability in demanding environments.

Comprehensive Service and Support

The Alternator Test Rig comes with onsite commissioning and training support, ensuring a seamless setup and immediate operational readiness. Service coverage across India assists distributors, exporters, manufacturers, suppliers, and wholesalers in maximizing productivity and minimizing downtime.

FAQs of Alternator test rig:

Q: How is the alternator test rig operated and controlled during testing?

A: The test rig can be operated via digital or manual control modes, allowing precise management of test speed, stroke, and functionality. The digital LCD display provides real-time performance data and accurate readings during operation.Q: What kind of tests can be performed with this rig?

A: This rig supports performance, endurance, and output regulation tests for alternators. Its accurate measurement systems and adjustable settings make it ideal for comprehensive automotive component evaluations.Q: When should onsite commissioning and training be expected after purchase?

A: Onsite commissioning and training are included with every purchase and are scheduled promptly after delivery, ensuring users receive expert guidance on installation, calibration, and operation.Q: Where is this test rig most suitable for use?

A: Designed for laboratories and workshop environments, the rigs robust construction and low noise output (less than 65 dB) make it suitable for professional automotive testing and evaluation across industrial settings in India.Q: What is the process for testing an alternator using this rig?

A: Testing involves mounting the alternator, configuring the test parameters using the digital or manual interface, and initiating the test cycle. Data such as output, endurance, and regulation are monitored on the digital LCD for precise assessment.Q: How does the rig ensure operator safety during operation?

A: The rig includes emergency stop and circuit breaker features, along with a low vibration design and IP54 protection class to safeguard both users and equipment throughout the testing process.Q: What benefits does this rig offer to automotive manufacturers and testing facilities?

A: By delivering accurate (1%) and repeatable test results, minimal noise and vibration, and onsite technical support, the rig enhances productivity, ensures reliable evaluations, and promotes safety for automotive component testing operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Test Rig Category

Endurance Test Rig

Minimum Order Quantity : 1 Piece

Interface Type : Touch Screen/USB

Port Size : Standard inch

Temperature : 10C to 60C

Mounting Type : Floor mounted

Frequency : 50 Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry