Call: 08045477360

Direct Methanol Full Cell Test Station

Direct Methanol Full Cell Test Station Specification

- Product Type

- Direct Methanol Full Cell Test Station

- Usage

- Testing methanol fuel cells performance and durability

- Material

- Stainless steel, chemical-resistant plastics, and precision electronics

- Capacity

- Single cell up to 10W output (customizable)

- Nominal Capacity

- Adjustable (depends on fuel cell tested)

- Terminal

- 4mm Safety Banana Sockets

- Sealed Type

- Sealed Reaction Chamber with Gas-tight Connectors

- Voltage

- 0-10V (Output voltage range depending on cell tested)

- Surface Finishing

- Powder Coated/Polished

- Size

- Standard laboratory benchtop size

- Dimension (L*W*H)

- 395 x 340 x 195 mm

- Weight

- Approx. 8 kg

About Direct Methanol Full Cell Test Station

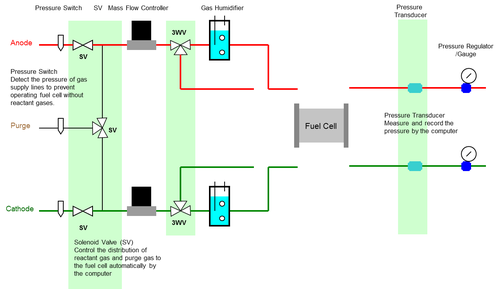

Direct Methanol Fuel Cell Test Station offered by our company, is designed and manufactured by making use of premium grade of raw materials and latest techniques. This station is used for testing the liquid fuel in the system. This station applies liquid fuel to the fuel cell to generate power. Direct Methanol Fuel Cell Test Station is widely used for its unique features like graphite separator plates, safe to use, easy installation, and excellent working. This test station is very effective and economical to use.

Advanced Flow Rate Control

Manage fuel supply with accuracy via the precise methanol flow control system. Fine-tune testing conditions for single-cell evaluations or customizable setups, ensuring reliable and repeatable results across a variety of research protocols.

Comprehensive Monitoring Suite

Monitor voltage, current, and temperature in real time using integrated digital displays. Data is easily logged through USB or RS232 ports, facilitating in-depth analysis and traceability of performance metrics during fuel cell operation.

Durable, Safe, and Adaptable Design

Built from stainless steel and chemical-resistant plastics, the systems sealed reaction chamber and gas-tight connectors provide a safe environment. Overcurrent, overtemperature protection, and leak-proof features enhance safety for users in laboratory and industrial contexts.

FAQs of Direct Methanol Full Cell Test Station:

Q: How does the precise liquid methanol flow control system enhance fuel cell testing?

A: The advanced flow control ensures that the methanol-water mixture is delivered accurately to the fuel cell, allowing for precise manipulation of test conditions. This leads to consistent, reliable performance evaluation and aids in optimizing cell design.Q: What safety features are included in this test station?

A: The station is equipped with a sealed reaction chamber with gas-tight connectors, overcurrent and overtemperature protection, as well as a leak-proof design. These features safeguard both users and equipment during operation.Q: When can this test station be used during fuel cell development?

A: It is suitable at every stage, from initial research and prototype development to routine performance and durability testing, making it indispensable in laboratory and industrial environments.Q: Where is this test station most commonly utilized?

A: Primarily used in research laboratories, universities, and industrial research divisions, its also popular among distributors, manufacturers, and suppliers across India and internationally for quality assurance and development.Q: What is the process for logging and analyzing performance data?

A: The system features external USB and RS232 interfaces for seamless data logging. Test parameters such as voltage, current, and temperature are recorded and can be exported to a PC for further analysis and reporting.Q: How does integrated humidification benefit fuel cell testing?

A: Integrated humidification allows simulation of varied operating conditions, providing insights into fuel cell performance under different humidity levels. This aids researchers in understanding durability and efficiency.Q: What are the main benefits of the corrosion-resistant, chemical-proof construction?

A: The use of stainless steel and specialty plastics ensures longevity and resilience, allowing the test station to handle harsh chemicals and repeated use without deterioration or performance loss.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fuel Cell Category

Fuel Cell control System

Minimum Order Quantity : 1 Piece

Capacity : Up to 10 kW

Sealed Type : Other, IP54 Rated Enclosure

Size : Standard

Board Thickness : 2.2 mm

Usage : Industrial and Laboratory Applications

20 KW Fuel cell inverter

Minimum Order Quantity : 1 ,

Capacity : 20 kW

Sealed Type : Other, Sealed, Weatherproof Enclosure

Size : Standard

Board Thickness : 6 mm

Usage : Industrial and Commercial Power Applications

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry