Label pulling machine

Label pulling machine Specification

- Control System

- Microcontroller based

- Motor Power

- 100 W

- Machine Type

- Label Pulling

- Lubricating System

- Manual lubrication

- Drive

- Single Phase Motor

- Voltage

- 220 V

- Cooling System

- Fan cooled

- Frame Type

- Steel

- Accuracy

- 0.2 mm

- Power Rating

- 0.1 kW

- Features

- High efficiency, Easy operation, Compact design

- Operating Temperature

- 0C to 50C

- Noise Level

- <60 dB

- Connectivity Options

- None

- Frequency

- 50 Hz

- Product Type

- Label Pulling Machine

- Power Source

- Electric

- Operating Type

- Manual/Automatic

- Power

- 100 W

- Pressure

- Adjustable pneumatic pressure

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 450 mm x 320 mm x 380 mm

- Weight (kg)

- 22 kg

- Color

- Grey

- Usage & Applications

- For labeling on bottles, boxes, and other packaging

Label pulling machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Western Union, Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Packaging Details

- CARTONS BOXES / WOODEN BOXES WITH THURMAKIL

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO ; 9001 ,2008

About Label pulling machine

Label Pulling Machine

Popular all over the leading market, our company is considered as one of the topmost manufacturers and suppliers of Label Pulling Machine. Our company is taking aid of revolutionary machines, which include CNC machines, cutting machines, welding machines, etc. due to which, we are able to manufacture wide range of pulling machine for our clients. Moreover, we are offering this Label Pulling Machine in the leading market as per the customer precise specifications and requirements.

Versatile Performance and Precision

Designed for high-precision labeling of bottles, boxes, and various packaging types, this machine ensures exceptional accuracy (0.2 mm) while supporting roll diameters up to 220 mm. The digital control system allows seamless adjustment of peeling speed to suit different production needs, ensuring labels are applied smoothly and consistently across diverse applications in industries such as pharma, food, cosmetics, and chemicals.

User-Friendly Features and Safety

Equipped with LED indicators for malfunction detection and digital speed adjustment, the label pulling machine prioritizes user convenience and operational safety. Its compact, steel frame and powder-coated finish facilitate desktop installation, while built-in overload and pneumatic pressure controls safeguard both operator and equipment during extended use.

Easy Maintenance and Efficient Operation

All components are easily accessible, making routine maintenance and troubleshooting straightforward and time-efficient. With low noise output, fan cooling, and manual lubrication, the machine is designed for long-lasting, reliable performance with minimal service interventions. Operator training included on delivery ensures users are quickly up to speed with both manual and automatic operating modes.

FAQs of Label pulling machine:

Q: How do I adjust the peeling speed on this label pulling machine?

A: Peeling speed can be precisely adjusted using the built-in digital control panel. This allows you to set the optimal speed for your specific labeling application, ensuring high efficiency and accurate results.Q: What benefits does the LED error display provide during operation?

A: The LED indicator swiftly alerts operators to any malfunction or error during machine operation, allowing for rapid troubleshooting and minimizing downtime in production processes.Q: When should maintenance be performed on the machine, and is it complicated?

A: Routine maintenance should follow the recommended intervals provided in the manual. With easily accessible parts and a manual lubrication system, maintenance tasks are straightforward and require minimal time, allowing for smooth, ongoing operation.Q: Where can this machine be effectively installed and used?

A: Due to its compact, desktop-friendly design and steel frame, the machine can be conveniently installed in various production settings, including factories and workshops concerned with labeling bottles, boxes, or other packaging.Q: What applications is the label pulling machine suitable for?

A: Its ideal for labeling on bottles, boxes, and other packaging materials in industries such as pharmaceuticals, food, cosmetics, and chemicals, making it a versatile choice for manufacturers and distributors.Q: How is operator training provided upon delivery?

A: Comprehensive operator training is included with delivery. This ensures that users are well-versed in both manual and automatic operation, safety protocols, and routine maintenance of the machine.Q: What are the main benefits of using this label pulling machine?

A: Users benefit from high accuracy, efficient operation, safety features like overload protection, adjustable pneumatic pressure, and easy operation. Its compact design, low maintenance requirements, and fast setup make it an excellent choice for modern packaging lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Machine Category

Block Clip fitting machine

Minimum Order Quantity : 1 Piece

Color : Blue/Grey

Usage & Applications : For fitting block clips in furniture and panel production

Machine Type : Block Clip Machine, Furniture Hardware Fitting

Product Type : Other, Block Clip Fitting Machine

Solder connector expansion stroke reduction machin

Minimum Order Quantity : 1

Color : Industrial Blue/Grey

Usage & Applications : Automated expansion and stroke reduction of solder connectors in cable harness, automotive, and electronics industries

Machine Type : Stroke Reduction Machine

Product Type : Other, Solder connector expansion stroke reduction machine

Features : Quick die change, electric stroke limiter, overheat protection, ergonomic worktable, safety guard

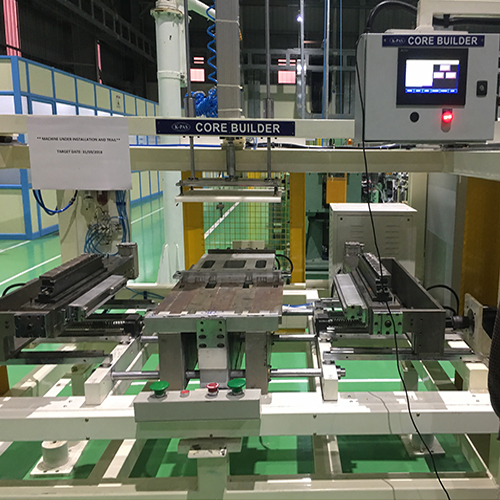

Core Builder

Color : Metallic grey

Usage & Applications : Transformer core assembly

Machine Type : Core assembly machine

Product Type : Other, Core Builder

Features : Automated core assembly Userfriendly interface High reliability

Special Purpose Machine

Color : Green and White

Usage & Applications : Rotor Balancing Automotive and Aerospace Components

Machine Type : Special Purpose Machine

Product Type : Other, Industrial Machinery

Features : High Precision Durable Construction User Friendly Operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry